The Institute takes immense pride in the consistent research contributions made by its faculty members, research scholars, and students. Our academic community actively engages in high-quality research and disseminates knowledge through reputed international and national journals, conferences, and book chapters.

Faculty and research scholars have published papers in peer-reviewed, indexed journals covering emerging and interdisciplinary domains. These publications reflect:

The Institute encourages active participation in prestigious national and international conferences. Conference proceedings published by reputed publishers further enhance the visibility and impact of our research work.

Faculty members have contributed scholarly book chapters in edited volumes published by recognized national and international publishers. These chapters:

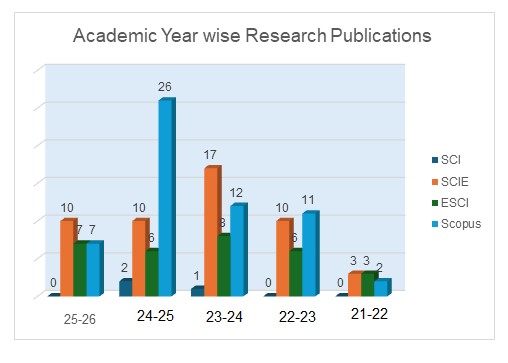

Improving the quality of research papers is critical for advancing knowledge and maintaining credibility in the academic and scientific communities. Mechanical Engg. department of PCCoE conducted training programs and workshops on research methodology, writing skills, ethical considerations, and publication standards. These sessions help researchers develop necessary skills and knowledge. Emphasizing publication ethics through guidelines and workshops helped researchers understand and adhere to ethical standards such as plagiarism detection, authorship criteria, and conflict of interest disclosures. Encouraging collaborative research initiatives across disciplines and institutions fosters diverse perspectives and strengthens the quality and impact of research outputs. Encouraging continuous improvement through post-publication discussions, corrections, and updates ensures that research publications remain current, accurate, and relevant. These efforts collectively contributed to enhancing the quality of research publications, advancing knowledge, and maintaining the credibility of academic and scientific communities. Total articles published in SCI/SCIE/ESCI/Scopus indexed journals for academic year 24-25,23-24,22-23 and 21-22 are 43,36,26 and 8 respectively. Continuous improvement in publication of research articles in SCIE/ESCI and Scopus indexed journals is recorded from academic year 21-22 to 25-26.

|

Journal Publication |

|||||||

|

Sr. No. |

Name of the Author |

Journal Name |

Title of the Article |

Date of Publication |

Scopus Q1/SCI/SCIE |

Scopus Q2/Q3/Q4/WoS |

DOI |

|

1 |

Dr. Sagar R Wankhede |

Energy storage |

Effect of the Fly Ash Nano Fluid in the Serpentine Channel on Cooling Efficiency Enhancement of EV Battery Thermal Management System |

22/7/25 |

Scopus |

Q2 |

|

|

2 |

Karan B. Khare, Dr. Dhirajkumar S Lal |

Engineering Research Express |

Design and development of a nozzle assembly for 3D

concrete |

24/06/2025 |

Scopus |

Q2 |

|

|

3 |

Dr.Abhay Lingayat, Dr. Pritam Das, Dr. VP Chandramohan |

Applied Thermal Engg |

A detailed review on performance enhancement of solar air collector systems |

14/07/2025 |

SCIE |

Q1 |

|

|

4 |

Dr.C.L.Ladekar,Gajanan Datar |

Josurnal of Renewable Energies |

Performance analysis of photovoltaic solar cells with passive cooling under controlled uniform radiation heat source |

23/07/25 |

Scopus |

Q4 |

|

|

5 |

Mr. H.H.Kadam |

Journal of polymer and composites |

An Experimental Investigation on the Determination of Critical Micelle Concentration (CMC) Of Various Surfactants Using the Surface Tension Method |

17/07/2025 |

ESCI |

Q4 |

|

|

6 |

Dr. Sagar Wankhede, Dr. Ajay Pingale, Dr. Shweta Patil |

Next Energy |

Experimental study of a novel nanofluid cooling system based on fly ash and serpentine channels for modular lithium-ion battery thermal control |

19/08/2025 |

Scopus |

Q3 |

|

|

7 |

Dr.N.Vivekanandan |

International Journal on Interactive Design and Manufacturing (IJIDeM) |

A CFD-based assessment of Azolla biofilters for sustainable indoor air purification in low-carbon buildings |

18-08-2025 |

ESCI |

Q2 |

10.1007/s12008-025-02377-5 |

|

8 |

Mr. H.H. Kadam |

Journal of Dispersion Science and Technology |

Experimental study: the impact of surfactant and nanoparticles concentration on the stability of alumina nanofluids |

6/9/2025 |

SCIE |

Q2 |

|

|

9 |

Dr. Ajay Pingale |

International Journal of Computational Materials Science and Engineering |

Mechanical behavior and fracture mechanisms of single-, double-, and triple-walled carbon nanotubes under tensile strain: A molecular dynamics study |

24/09/2025 |

ESCI, Scopus |

Q2 |

|

|

10 |

Dr.N.A.Mandhare |

Journal of Thermal Engg |

Performance of Mylar and Teflon as compound parabolic

concentrators |

Sept,2025 |

ESCI,Scopus |

Q3 |

|

|

11 |

Mr. H.H. Kadam, Dr. A.N. Kore |

Journal of Surfactant and Detergents |

Experimental Study: An Effect of Rhamnolipid Bio-Surfactant on Heat Transfer Performance of Al2O3 Nanofluids in Horizontal Tube |

02/10/2025 |

SCIE |

Q2 |

|

|

12 |

Dr. Rita Shrikant Pimpalkar |

ES Energy and Environment |

Analysis of Energy Conservation Measures using Calibrated Building Energy Simulation Model |

22/09/2025 |

Scopus |

Q2 |

|

|

13 |

Dr. Ajay Pingale |

Molecular Simulation |

Fundamental insights of quasi-static straininduced fracture dynamics in vacancy-defected hexagonal boron nitride: an atomistic approach |

08/10/2025 |

SCIE, Scopus |

Q2 |

|

|

14 |

Dr. Ajay Pingale |

Journal of Applied Physics |

Continuum and computational modeling of flexoelectricity in nanomaterials: A review |

17/11/2025 |

SCIE, Scopus |

Q1 |

|

|

15 |

Dr. Jayashri Wagh |

Heat Transfer Wiley |

Comparative Study on CFD‐Based Performance Optimization of Butterfly Valve Through Geometric Modifications for Pressure‐Drop Reduction |

07/11/2025 |

ESCI. Scopus |

Q1 |

|

|

16 |

Dr.N.Vivekanandan |

Cognitive Neurodynamics |

Bio-inspired spiking neural network for modeling and optimizing adaptive vertigo therapy |

11/24/2025 |

SCIE, Scopus |

Q2 |

|

|

17 |

Dr. Ajay Pingale |

Engineering Research Express |

Atomistic Insights into Thermo-tensile Response of CuNi Nanowires: Uncovering The Mechanism of High-temperature Performances |

05/12/2025 |

ESCI. Scopus |

Q2 |

|

|

18 |

Dr.N.A.Mandhare |

Journal of Thermal Analysis and Calorimetry |

A critical review on Solar cooking system for residential application |

11/12/2025 |

SCIE,Scopus |

Q1 |

10.1007/s10973-025-14962-7 |

|

19 |

Dr. Pravin Kale, Prof. Amit Panchwadkar, Dr. Ajay Pingale |

UPB Scientific Bulletin, Series D: Mechanical Engineering |

Enhancing Crush Box Energy Absorption Capacity: A Numerical Investigation Under Quasi-Static Axial Crushing |

21/12/2025 |

Scopus |

Q4 |

https://www.scientificbulletin.upb.ro/rev_docs_arhiva/rez813_434433.pdf |

|

20 |

Dr. A.N. Kore, Mr. H.H. Kadam, |

Heat Transfer Wiley |

Numerical Analysis of Helical Coil‐Inserted Tubes Based on Thermohydraulic Performance and Development of Correlations for Heat and Fluid Flow |

01/12/2025 |

ESCI. Scopus |

Q1 |

|

|

21 |

Dr.N.Vivekanandan |

Building and Environment |

A coupled ODE–CFD framework for size-resolved modeling of indoor airborne microplastic mitigation with Azolla biofilters |

01/01/2026 |

SCIE, Scopus |

Q1 |

|

|

22 |

Dr.Sanjay Salve, Dr.N.Vivekanandan, Dr.Mahadev Madgule |

High-yield integrated solar still with flat-plate collector and internal condensers for decentralized potable water production in arid regions |

03/01/2026 |

SCIE, Scopus |

Q1 |

||

|

23 |

Dr.N.Vivekanandan |

Journal of Engineering Education Transformations |

Integrating AI Ethics and Sustainability Through Experiential and Data-Driven Curriculum Innovation at PCCOE |

02/01/2026 |

Scopus |

Q2 |

|

|

24 |

Dr.N.Vivekanandan |

Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering |

|

2026/2 |

SCIE, Ccopus |

Q2 |

|

|

Conference Publications |

|||||||

|

1 |

Dr.N.Vivekanandan |

Communications in Computer and Information Science, vol 2684. Springer |

A Vision-Guided Autonomous Weeding Robot Using Image-Based Weed Classification for Sustainable Agriculture |

02 January 2026 |

Scopus |

Q4 |

|

|

Book Chapter |

|||||||

|

1 |

Dr. Puja More |

Lecture Notes in Mechanical Engineering (book chapter) |

Identification of Wear Particles Obtained Through Gearbox Using Convolution Neural Network |

11/2025 |

Scopus |

Q4 |

|

|

2 |

Ummid Shaikh |

Recent Advances in Thermal and Fluid Science. Lecture Notes in Mechanical Engineering. Springer, Singapore. |

Comparative Study of Battery Thermal Management: Analyzing Natural Convection, Immersion Cooling, and Hybrid Immersion-Thermoelectric Techniques. |

8/11/2015 |

Scopus |

Q4 |

10.1007/978-981-96-8508-0_12 |

|

Journal Publication |

||||||

|

Sr. No. |

Name of the Author |

Journal Name |

Title of the Article |

Date of Publication |

Scopus Q1/SCI/SCIE |

|

|

1 |

Upendra Maurya |

Tribology International (Science Direct) |

Nano-innovations in lubrication: Unveiling the synergistic boundary lubrication potential of zinc titanate with phosphonium ionic liquid |

13th July 2024 |

SCIE, Scopus, |

|

|

2 |

Dr.Sagar Wankhede,Dr.Abhijeet N. Kore,Dr.Pravin Kale |

Wiley Heat Transfer |

Experimental investigation on an innovative |

27-Aug-2024 |

Scopus |

|

|

3 |

Gaffar Gulab Momin |

Journal of Mines, Metals and Fuels |

The Performance and Emission Analysis of a Diesel Engine Using Vegetable Oil Blends and Bio-Diesel as Fuel-A Review |

Sept,2024 |

Scopus |

|

|

4 |

Mrs . Shweta Patil ,Dr.Sagar Wankhede |

Wiley Heat Transfer |

An air‐cooled cylindrical Li‐ion 5 × 5 battery module with a novel flow‐diverting arrangement and variable vent positions for electric vehicles: A numerical thermal analysis |

9-Sep-2024 |

Scopus |

|

|

5 |

Dr Rahul Mali |

UPB Scientific Bulletin, Series D: Mechanical Engineering |

A comparative evaluation and analysis of free-form surface deviations using articulated arm CMM and 3D scanner |

1-Sep-2024 |

Scopus |

|

|

6 |

Dr. Jayesh Chordiya, Dr. Padmakar Deshmukh |

Archive of Mechanical Engineering |

Numerical study on the effect of strategically placed multiple diathermal obstructions within a porous enclosure |

30-Sep-2024 |

Scopus |

|

|

7 |

Dr. Upendra Maurya |

Surface Review and Letters, |

MORPHOLOGY of WEAR DEBRIS during DRY SLIDING of Ti6Al4V/TiC COMPOSITE at ELEVATED TEMPERATURES in VACUUM CONDITIONS |

Sep-2024 |

SCI |

|

|

8 |

Mrs. Jayashri Wagh |

African journal of biomedical research |

Natural Fiber Thermoplastic Composites For Mechanical and Biodegradability Properties |

Oct-2024 |

scopus |

|

|

9 |

Mrs.Rita Pimpalkar,Dr.Mahadev Madgule |

Journal of Concurrent Engineering: Research and Applications |

Integration of Lean manufacturing system with novel intuitive fuzzy syncretic lean frame work to improve the overall equipment effectiveness |

29th Oct 2024 |

Scopus |

|

|

10 |

Mrs. Varsharani Yogesh Gaikhe |

Journal of Materials Engineering and Performance |

Experimental Investigations into the Effect of Infill Patterns on the Microstructure and Mechanical Properties of Inconel 718 Using Laser-Directed Energy Deposition |

30th Oct 2024 |

Scopus, SCIE |

|

|

11 |

Mr. Ishan Sathone |

Biomedical Physics & Engineering Express |

Finite element analysis and optimization studies on tibia implant of SS 316L steel and Ti6Al4V alloy |

15 October 2024 |

Scopus |

|

|

12 |

Dr. Mahadev Madgule |

Journal of The Institution of Engineers (India): Series D |

Design and Analysis of Carbon Reinforced Composite Plate

|

04th Nov 2024 |

Scopus |

|

|

13 |

Gaffar Gulab Momin |

International Journal of Heat And Technology |

Use of Neem Vegetable Oil Blends with Diesel Fuel on Variable Compression Ratio Engine an Experimental Approach |

31/10/2024 |

Scopus |

|

|

14 |

Ajay Pingale |

Heat Transfer, Wiley |

Experimental Investigation of Pool Boiling Heat Transfer on Cu─Al2O3 Composite Coated Patterned Surfaces Using Refrigerant R‐134a |

23/11/2024 |

Scopus, ESCI |

|

|

15 |

Dr.N.A.Mandhare |

Heat Transfer, Wiley |

Computational Analysis and Experimental Investigation of the Performance of an Evacuated Tube Solar Air Heater Incorporating Therminol-55 as a Thermal Energy Storage Medium |

28/11/2024 |

Scopus, ESCI |

|

|

16 |

Mrs. Jayashri Wagh |

Discover Applied Sciences, Springer International Publishing |

Enhanced biodegradability and mechanical properties in green composites: a Taguchi approach |

28/12/2024 |

Scopus, ESCI |

|

|

17 |

Dr. Jayesh Chordiya, Dr. Padmakar Deshmukh |

Heat Transfer, Wiley |

Numerical Study on the Effect of Trapezoidal-Wave Shaped Partition on Natural Convection Flow Within a Porous Enclosure |

16/12/2024 |

Scopus, ESCI |

|

|

18 |

Gaffar Gulab Momin |

Journal of Advanced Research in Fluid Mechanics and Thermal Sciences |

“Performance And Emission Analysis of a C.I.Engine Fueled With Preheated Neem Straight Vegetable Oil-Diesel Blend At Various Compression Ratios” |

Nov.2024 |

Scopus |

|

|

19 |

Dr.N.A.Mandhare |

International Journal on Interactive Design and Manufacturing (IJIDeM) |

Computational investigation of explosion avoidance system of multi tier Li-ion battery pack |

17/12/2024 |

Scopus, ESCI |

|

|

20 |

Shweta Patil |

Wiley Energy Storage |

Improving Electric Vehicle Air-Cooled |

14/12/2024 |

Scopus |

|

|

21 |

H.H. Kadam |

Journal of Surfactant and Detergent |

A thorough analysis of surfactant |

05-02-2025 |

||

|

22 |

H.H. Kadam |

Journal of Surfactant and Detergent |

Influence of rhamnolipids, anionic surfactants, |

11-2-2025 |

||

|

23 |

Ishan Stahone |

|

Study of Influence of Hole Distance on the Strength of Locking Compression Plate Implants |

07-01-2025 |

||

|

24 |

Dr. Pravin Kale, Prof. Amit Panchwadkar, Dr. Ajay Pingale |

Journal of Mines, Metals and Fuels |

Bead Pattern Optimization for Sheet Metal Panel using 3D Experience Platform |

24/02/2025 |

Scopus |

|

|

25 |

Dr. Sagar Wankhede, Dr. Ajay Pingale |

Energy Storage and Saving |

Experimental investigation on thermal management of lithium-ion battery pack for formula student electric vehicle using air-cooling system |

26/02/2025 |

Scopus |

|

|

26 |

Ummid Shaikh |

Journal of the Brazilian Society of Mechanical Sciences and Engineering |

Evaluating PCM-based thermal management for lithium-ion batteries under diverse surrounding tem-peratures: A numerical study |

03-02-2025 |

SCIE |

|

|

27 |

Dr. Jayesh Chordiya, Dr. Padmakar Deshmukh |

Heat Transfer, Wiley |

On thermal convection effect due to fluid-blocks of varying shapes embedded in a porous medium |

02-03-2025 |

Scopus, ESCI |

|

|

28 |

Dr.N.A.Mandhare,Dr.R.A.Gujar |

International Journal for Numerical Methods in Fluids |

Comparative Analysis of Reinforcement Learning Agents for Optimizing Airfoil Shapes |

12-3-25 |

Scopus. SCIE |

|

|

29 |

Mrs.Rita Pimpalkar |

Journal of Concurrent Engineering: Research and Applications |

A smart solar PV monitoring system using ioT |

14/03/2025 |

Scopus |

|

|

30 |

Dr. Pravin Kale, Dr. Ajay Pingale |

Journal of Mines, Metals and Fuels |

Analysis of Lifting Eye Bolt for Different Materials and Cross Sections |

27/03/2025 |

Scopus |

|

|

31 |

Dr. Pravin Kale, Dr. Ajay Pingale |

Journal of Mines, Metals and Fuels |

Virtual Drop Test Analysis of Corrugated Box Packaging for Material Handling |

27/03/2025 |

Scopus |

|

|

32 |

Dr. Pravin Kale, Dr. Ajay Pingale |

Journal of Mines, Metals and Fuels |

Design and Analysis of Crane Hook with Trapezoidal Cross-Section: A Study on Static Structural and Modal Analysis |

27/03/2025 |

Scopus |

|

|

33 |

Dr. J. P. Wagh |

Journal of the Chinese Institute of Engineers |

Mechanical characterization of flax-mat reinforced PLA/PBS green composite laminates |

27/03/2025 |

Scopus. SCIE |

|

|

34 |

Dr Rahul Mali |

Applied Physics A Materials Science & Processing |

NiO nanosheet-assembled chemiresistive sensor for NO2 detection |

06/03/2025 |

Scopus. SCIE |

|

|

35 |

Dr.N.A.Mandhare,Dr.R.A.Gujar |

Mathematical Modelling of Engineering Problems |

Reinforcement Learning-Driven Airfoil Optimization: Enhancing Aerodynamic Performance |

31/3/2025 |

Scopus |

|

|

36 |

Mrs.Rita Pimpalkar |

Science and Technology for Energy Transition |

Reliability analysis and life cycle costing of rooftop solar photovoltaic (PV) system operating in a composite environment |

April 2025 |

SCIE |

|

|

37 |

Dr. Ajay Pingale |

Multidisciplinary Reviews |

A bibliometric exploration of religiosity and purchase intention |

22/04/2025 |

Scopus |

|

|

38 |

Dr. Abhijeet N Kore |

Journal of food process engineering |

Feasibility of Liquid Desiccant Dehumidification System for Low-Temperature Drying Applications |

18/04/2025 |

SCIE and Scopus |

|

|

39 |

Mrs S.V.Patil |

International Journal of Ambient Energy |

An experimental study on the influence of environmental conditions on the temperature of the battery pack during discharge in an electric vehicle, utilising thermal insulating material |

26/5/2025 |

Scopus |

|

|

40 |

Chandrakishor Ladekar |

International Journal of System Assurance Engineering and Management |

Utilizing red fox method for improvement of engine performance and emission control in hydrogen-cooked oil diesel engines |

15/05/2025 |

Scopus and ESCI |

|

|

41 |

Dr.N.A.Mandhare.Shamkant Waghmare,Omkar Yadav |

Concurrent Engineering Reserarch and applications |

Design of innovative human-centric tyre on road pressure regulation system for increasing driver safety and fuel efficiency |

12/6/2025 |

Scopus |

|

|

42 |

Dr. Mahadev Madgule, Dr. Ajay Pingale, Dr. Govind Waghmare, Dr. Raju Bhosale |

Concurrent Engineering Research and Applications |

Implementation of Taguchi approach on the aluminum alloy 2219 metal matrix composites to improve the quality of the drilling process |

20/06/2025 |

Scopus |

|

|

43 |

Dr. Govind Waghmare, Dr. Ajay Pingale, Dr. Mahadev Madgule |

Journal of Environmental Nanotechnology |

Experimental Study of Pool Boiling Characteristic of Al2O3-coated Aluminum Surfaces |

30/06/2025 |

Scopus |

|

|

Conference Publications |

||||||

|

1 |

Dr. Ajay Pingale |

E3S Web of Conferences |

Sustainability in magnetic metal-carbon nanocomposites: A comprehensive review of manufacturing, characterization, and applications |

23-Jul-2024 |

Scopus |

|

|

2 |

Mrs. Shweta Patil |

SAE Technical Paper, SAE International |

Insights into Retrofitting Internal Combustion Engine to battery electric vehicle for ecofriendly technology |

02-20-2025 |

doi:10.4271/2025-01-5009 |

|

|

Book Chapter |

||||||

|

1 |

Dr.N.A.Mandhare |

Advances in Clean Energy and Sustainability, Volume 2,Springer Nature |

An Effective Model for Performance Prediction of a Centrifugal Pump with Nose Caps Using ANN |

27th sept,2024 |

Scopus |

|

|

2 |

Dr. Rahul A Mali |

Lecture notes in Electrical Engineering, Vol 1226 |

Application of Evolutionary Computational Algorithms to Estimate Responses in Milling Al7075 |

15/10/2024 |

||

|

3 |

Dr.N.Vivekanandan |

Lecture Notes in Mechanical Engineering (LNME) |

|

Electronic ISSN |

28 December 2024 |

|

|

Journal Publication |

|||||||

|

Sr. No. |

Name of the Author |

Journal Name |

Title of the Article |

Date of Publication |

Scopus Q1/SCI/SCIE |

Scopus Q2/Q3/Q4/WoS |

DOI |

|

1 |

G. Waghmare, R. R. |

International Journal of Quality and Reliability Management |

Multi-response optimization for a low-cost multi-dimpling process |

July 2023 |

ESCI, |

Q1 |

|

|

2 |

Abhijeet N. Kore, S. S. Lakade, Atul Padalkar |

Journal of Food Process Engineering |

Experimental investigation of single open pan heat exchanger for jaggery making: A novel technique to enhance the performance of a system |

July 2023 |

SCIE |

Q2 |

|

|

3 |

Gujar R., Warhatkar H., Kale A. |

Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science |

Finite element analysis (FEA) of femur to predict biomechanical properties and its validation |

July 2023 |

SCIE |

Q2 |

|

|

4 |

Abhay Lingayat, Pritam Das, Mulatu C. Gilago, Chandramohan |

Solar Energy |

A detailed assessment of paraffin waxed thermal energy storage medium for solar dryers |

Sept. 2023 |

SCIE |

Q2 |

|

|

5 |

Borgaonkar A., Syed I. |

Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology |

Eco-friendly sustainable machining with MoS2-based solid lubricant |

September 2023 |

SCIE |

Q2 |

|

|

6 |

Sagar Wankhede, and L. Kamble |

Energy Storage |

A novel battery cooling system using nanofluids on MATLAB Simulink |

October 2023 |

Scopus Q2 |

Q2 |

|

|

7 |

Sagar Wankhede, and L. Kamble |

Energy Storage |

Performance investigation of electric vehicle battery thermal management system using nano fluids as coolants on ANSYS CFX software |

October 2023 |

Scopus Q2 |

Q2 |

|

|

8 |

Madgule M., Deshmukh P., Perveen K., Qamar M.O., Razak A., Wodajo A.W. |

Advances in Mechanical Engineering |

Experimental investigation on mechanical properties of novel polymer hybrid composite with reinforcement of banana fiber and sugarcane bagasse powder |

October 2023 |

SCIE |

Q2 |

|

|

9 |

Roy A., Kale S., Lingayat A.B., Sur A., Arun S., Sengar D., Gawade S., Wavhal A. |

Journal of the Brazilian Society of Mechanical Sciences and Engineering |

Evaluating energy-saving potential in micro-cold storage units integrated with phase change material |

October 2023 |

SCIE |

Q1 |

10.1007/s40430-023-04434-0 |

|

10 |

More P.P., Jaybhaye M.D. |

Journal of Failure Analysis and Prevention |

Wear Particle Classification Using Ferrographic Analysis in Gearbox System Considering Area and Perimeter |

October 2023 |

SCIE |

Q3 |

|

|

11 |

Dr. Abhay Lingayat |

Journal of the Brazilian Society of Mechanical Sciences and Engineering |

Evaluating energy-saving potential in micro-cold storage units integrated with phase change material |

October 2023 |

SCIE, Scopus Q2 |

Q2 |

|

|

12 |

Dr. Upendra Maurya |

Journal of Failure analysis and Prevention |

Estimating the Dry-Wear Behavior of Rolling/Sliding Bearings (PB, Gunmetal, and Al6061)–Tribo Materials |

October 2023 |

ESCI,Scopus Q3 |

Q3 |

|

|

13 |

Dr. Upendra Maurya |

Journal of Material and Engineering |

Unravelling the Effect of Chain and Branch Content on Viscosity of Polyisobutylene-Mineral Oil Blends by Modelling and its Tribological Properties |

March 2024 |

ASCI |

-- |

10.61552/JME.2024.03.005 |

|

14 |

Dr. Abhay Lingayat |

Sensors and Actuators A: Physical |

A critical assessment on micro-blowers and pumps for different engineering applications |

November 2023 |

SCIE, Scopus Q1 |

Q1 |

|

|

15 |

Dr. Ajay Pingale |

Journal of Engineering Thermophysics |

Saturated Pool Boiling Heat Transfer of R-141b on Al2O3 Nano-Structured Surfaces Fabricated by Dip-Coating Method |

14-Dec-2023 |

SCIE, Scopus Q3 |

Q3 |

|

|

16 |

Dr. Chandrakishor L. Ladekar |

International Journal of Power and Energy Systems, |

CFD ANALYSIS OF 210 MW BOILER’S ECONOMISER FOR DETECTING AREA AND CAUSES OF TUBE FAILURE |

December 2023 |

ESCI, Scopus Q4 |

Q4 |

|

|

17 |

Mrs.Rita shrikant Pimpalkar |

Journal of mines,metals and fuels |

An artificial intelligence and machine learning model to estimate the cleaning periodicity for Dusty solar photovoltaic (PV) modules in a composite environment |

December 2023 |

Scopus Q4 |

Q4 |

2023, 10.18311/jmmf/2023/41769 |

|

18 |

Dr. Chandrakishor Ladekar |

Journal of Mines, Metals and Fuels |

Performance Investigation of Spark Ignition Engines (SIE) using Biofuel Blended with N-Propanol Fuel Additive |

December 2023 |

SCOPUS Q4 |

Q4 |

DOI: 10.18311/jmmf/2023/41767 |

|

19 |

Mr. Nilesh Gaikwad |

Int. J. Vehicle Systems Modelling and Testing |

Design and development of a Formula Student electric racecar’s control system |

January 2024 |

Scopus |

Q4 |

10.1504/IJVSMT.2023.10060220 |

|

20 |

Dr. Ajay Pingale |

Thermo |

An Experimental Investigation on the Pool Boiling Heat Transfer of R-134a on Microporous Cu-MWCNT Composite Surfaces. |

17-Jan-2024 |

Scopus, ESCI |

Q3 |

|

|

|

Mrs.Rita shrikant Pimpalkar |

The Journal of The Institution of Engineers (India): Series C |

Failure Modes and Effects Analysis of Polycrystalline Photovoltaic Modules Exposed to the Composite Climate of India |

14 February 2024 |

Scopus |

Q3 |

|

|

21 |

Mr.S.R.Wankhede |

Wiley Energy Storage |

A review of Li-ion battery temperature control and a key future perspective on cutting-edge cooling methods for electrical vehicle applications |

27 February 2024 |

Scopus |

Q3 |

|

|

22 |

Dr. Avinash Borgaonkar |

Materials and Manufacturing Processes |

Tool wear analysis in AISI 52100 steel machining with sustainable approach |

29 February 2024 |

SCI |

Q2 |

|

|

23 |

Dr. Chandrakishor Ladekat |

World Journal of Engineering [ISSN 1708-5284] |

Design and analysis of serviceable cantilever fit snap in automotive plastic parts |

13 Feb 2024 |

SCOPUS, ESCI |

Q3 |

|

|

24 |

Dr. Puja P More |

Journal of Failure Analysis and Prevention |

A Condition-Based Maintenance of Two-Stage Gearbox Using Analytical Ferrography |

20 Feb 2024 |

ESCI |

Q3 |

|

|

25 |

Dr. Ajay Pingale |

UPB Scientific Bulletin, Series B: Chemistry and Materials Science |

Prediction and Optimization of Microhardness and Corrosion Behaviour of CuNi-Gr Composite Coatings |

15 March 2024 |

Scopus, ESCI |

Q4 |

https://www.scientificbulletin.upb.ro/rev_docs_arhiva/reza50_317206.pdf |

|

26 |

Chandrakishor Ladekar |

Elsvier, Fuel |

Intelligent Decision-Based Hydrogen-Biodiesel engine to improve engine performance |

March 2024 |

SCIE, WOS, SCOPUS |

Q1 |

|

|

27 |

Ummid Shaikh |

Journal of Advanced Research in Fluid Mechanics and Thermal Sciences |

A Review on Cooling Methods of Lithium-Ion Battery Pack for Electric Vehicles Applications |

March 2024 |

Scopus |

Q3 |

|

|

28 |

R. B. Patil, P. V. Ingle, and P. A. Deshmukh |

Innovative Higher Education |

A Methodology for Improving the Quality of the Research Article Publications in Engineering Institutions in India: A Case Study |

2024 |

ESCI,Scopus |

Q2 |

10.1007/s10755-024-09703-x |

|

29 |

AkshaySonawane, Nukulwar, M.R. and P. A. Deshmukh |

GMSARN International |

Design and Development of a Hybrid Power Generating System using Solar and Wind Power with a Streetlamp as an Application |

-- |

Scopus |

Q4 |

-- |

|

30 |

Dr. Ajay Pingale |

Journal of Alloys and Metallurgical Systems (Elsevier) |

Remarkable tribo-mechanical, anticorrosion and antibacterial properties of ZnCu/GNPs composite coatings prepared by electro-co-deposition technique |

27-May-2024 |

Scopus |

Q4 |

|

|

31 |

Mrs Rita shrikant Pimpalkar |

Sustainability |

A Reliability and Risk Assessment of Solar Photovoltaic Panels Using a Failure Mode and Effects Analysis Approach: A Case Study |

16th May |

Scopus, SCIE |

Q1 |

Sustainability 2024, 16(10), 4183; https://doi.org/10.3390/su16104183 ,Scopus,SCIE |

|

32 |

Abhijeet N Kore & Suraj Meshram |

International Journal of Sustainable Energy |

Life cycle testing and reliability analysis of prismatic lithium-iron-phosphate cells |

17 May 2024 |

Scopus, SCIE |

Q2 |

|

|

33 |

Ummid Shaikh |

Heat Transfer Research |

THERMAL PERFORMANCE ANALYSIS OF |

22-05-2024 |

Scopus, SCIE |

Q2 |

|

|

34 |

Mrs. Jayashri Wagh, Dr. M. Madgule |

Journal of Reinforced Plastics and Composites |

Investigative studies on natural fiber reinforced composites for automotive bumper beam applications |

11 June 2024 |

Scopus, SCIE |

Q1 |

|

|

35 |

Abhijeet N. Kore, Sagar R. Wankhede |

Heat Transfer |

Heat transfer analysis in open pan heatexchanger (OPHE) with different cross‐ sections of conduits for jaggery processing |

27 June 2024 |

Scopus |

Q2 |

|

|

36 |

Vikram Aher |

Lasers in Manufacturing and Materials Processing (Springer Nature) |

A Comprehensive Review on Laser Bending of Advanced Materials |

28 June 2024 |

Scopus |

Q2 |

|

|

Conference Publications |

|||||||

|

1 |

Gauri Phadtare |

(proceedings articles/conference papers) Proceedings from the International Conference on Hydro and Renewable Energy |

Analytical Approach for Hybrid Line and Point Solar Concentrator |

19 April 2024 |

Scopus |

Q4 |

https://doi.org /10.1007/978-981-99-6616-5_4. |

|

2 |

Dr. Mahadev Madgule |

AIP Conference Proceedings 0094243X, 15517616 |

A review on – Variants in specimen preparation of natural fiber composites |

26-27 Aug 2022 |

Scopus |

Q4 |

|

|

3 |

Mr. Ishan Sathone |

AIP Conference Proceedings 0094243X, 15517616 |

A review on failure of tibia bone and associated implant |

26-27 Aug 2022 |

Scopus |

Q4 |

|

|

4 |

Mr. Shriyash S. Shinde |

ICMSE 2023 |

Advances in hybrid aluminium metal matrix composite produced by stir casting route: A review on applications and fabrication characteristics |

23rd and 24th Nov 2023 |

Scopus |

Q4 |

|

|

5 |

A Lingayat, J Goyal |

AIP Conference Proceedings 0094243X, 15517616 |

Experimental analysis of thermal energy storage with PCM for the application of solar water heater |

March 2024 |

Scopus |

Q4 |

|

|

6 |

Chandrakishor Ladekar |

AIP Conference Proceedings 0094243X, 15517616 |

Fundamentals of Nadi Pariksha: A review of ancient ayurvedic holistic diagnostic tool |

27 March 2024 |

Scopus |

Q4 |

|

|

7 |

Dr. Ajay Pingale |

Materials Today: Proceedings |

Recent developments of sonication process in stability and efficiency of nanofluid-based coolants: A review |

16 July 2023 |

Scopus |

Q4 |

|

|

Book Chapter |

|||||||

|

Name of the authors |

Title of Book/Book chapter |

Chapter |

ISBN No. |

||||

|

1 |

Dr. Avinash Borgaonkar |

New Advances in Materials Technologies: Experimental Characterizations, Theoretical Modeling, and Field Practices' |

Mechanical and Tribological Characteristics of Two-Dimensional (2D) Nanomaterials |

ISBN: 9781003459262. |

|||

|

2 |

Mrs.Rita Shrikant Pimpalkar |

Rest Publisher |

Computational Engineering (book) |

ISBN:978-81-969420-0-7 |

|||

|

Journal Publication |

|||||||

|

Sr. No. |

Name of the Author |

Journal Name |

Title of the Article |

Date of Publication |

Scopus Q1/SCI/SCIE |

Scopus Q2/Q3/Q4/WoS |

DOI |

|

1 |

Rajkumar B. Patil, S. S. Patil, G. Gupta, A. K. Bewoor |

A Generalized Model Selection Framework for Multi-State Failure Data Analysis |

International Journal of Quality and Reliability Management |

39 |

7 |

1637-1647 |

|

|

2 |

A. B. Shindde, Rajkumar B. Patil |

Multi-objective Optimization of Split and Recombine Micromixer Using Grey Relational Analysis Method |

International Journal of Quality and Reliability Management |

39 |

7 |

1577-1594 |

|

|

3 |

M. Saini, D. Goyal, A. Kumar, Rajkumar B. Patil |

Availability Optimization of Biological and Chemical Processing Unit using Genetic Algorithm and Particle Swarm Optimization |

International Journal of Quality and Reliability Management |

39 |

7 |

1704-1724 |

|

|

4 |

Sagar Wankhede, P. Thorat, S. Shisode, S. Sonawane |

A study of different battery thermal management systems for battery pack cooling in electric vehicles |

Heat Transfer |

51 |

8 |

7487-7539 |

|

|

5 |

S. A. Rawandale, V. N. Kalbande, A. Bodhe, U. Rawandale, and R. Patil |

Estimating the employment opportunity of engineering students with the aid of fuzzy logic controller |

International Journal of Engineering Trends and Technology |

70 |

3 |

319-326 |

|

|

6 |

Sanjay Salve, and A. Fulambarkar |

Experimental studies on drying characteristics of green chilies in a solar dryer |

Journal of Thermal Engineering |

8 |

5 |

587-594 |

|

|

7 |

Abhay Lingayat, |

Current status and prospect of integrating solar air heating systems for drying in various sectors and industries |

Sustainable Energy Technologies and Assessments |

52 |

C |

102274 |

|

|

8 |

Ashish Kumar, M. Saini, Rajkumar B. Patil, Sameer Al-Dahidi, and M. A. Mellal |

Reliability, Availability, Maintainability, and Dependability of Tube-Wells Integrated with Underground Pipelines in Agricultural Fields for Irrigation |

Advances in Mechanical Engineering |

14 |

8 |

1-17 |

|

|

9 |

S. S. Singh, Akash Awale, B. Nahak |

Assessment the surface characteristics of heat-treated AISI 1040 steel using magnetic non-destructive techniques |

Russian Journal of Nondestructive Testing |

58 |

5 |

369-380 |

|

|

10 |

Ganesh R. Gawale, G. N. Srinivasulu, Abhay Lingayat |

Experimental investigation on diesel ignited dual fuel homogeneous charge compression ignition engine for the selection of suitable alcohol-based fuel |

Journal of Cleaner Production |

380 |

1 |

135048 |

|

|

11 |

Anindita Roy, Rajkumar B. Patil, Rajarshi Sen |

The effect of fast charging and equalization on the reliability and cycle life of the lead acid batteries |

Journal of Energy Storage |

55 |

D |

105841 |

|

|

12 |

Suyog S. Patil, Anand K. Bewoor, and Rajkumar B. Patil |

A New Approach for Failure Modes, Effects, and Criticality Analysis Using ExJ-PSI Model – A Case Study on Boiler System |

Applied Sciences |

12 |

- |

11419 |

|

|

13 |

Sagar Wankhede, P. Thorat, S. Shisode, S. Sonawane, and Wankhede |

Energy consumption estimation for electric two-wheeler using different drive cycles for achieving optimum efficiency |

Energy Storage |

- |

- |

- |

|

|

14 |

V. Y. Bhalerao, and S. S. Lakade |

Enhancement of Tribological Properties of Cubic and Hexagonal Boron Nitride Nanoparticles Impregnated on Bearing Steel via Vacuum Heat Treatment Method |

Coating |

12 |

22 |

1940 |

|

|

15 |

A. A. Mathew, V. Thangavel, N. A. Mandhare, and M. R. Nukulwar |

Latent and sensible heat thermal storage in a heat pipe-based evacuated tube solar dryer: A comparative performance analysis |

Journal of Energy Storage |

57 |

- |

106305 |

|

|

16 |

Mahadev Madgule, C. G. Shreenivasa |

Determination of porosity and microstructure studies of wax-based Aluminium metal foam |

International Journal of Microstructure and Materials Properties, Inderscience |

16 |

4 |

292-302 |

|

|

17 |

B. S. Kale, K. S. Bhole, N. A. Mandhare, and S. V. Patil |

Finite element analysis and deployment of analytical hierarchical process for design of the structural framework for micro-actuators of vehicle crash box |

International Journal on Interactive Design and Manufacturing |

- |

- |

- |

|

|

18 |

N. R. Patil, S. Rawandale, N. Rawandale, U. Rawandale, and S. Patil |

An efficient stacking-based NSGA-II approach for predicting type 2 diabetes |

International Journal of Electrical and Computing Engineering |

13 |

1 |

1015-1023 |

10.11591/ijece.v13i1.pp1015-1023 |

|

19 |

P. R. Sonawane, S. Bhandari, Rajkumar B. Patil, and S. Al-Dahidi |

Reliability and Criticality Analysis of a Large-Scale Solar Photovoltaic System Using Fault Tree Analysis Approach |

Sustainability, MDPI |

15 |

5 |

4609 |

|

|

20 |

Sagar Wankhede, L. Kamble, and P. Thorat |

Differentiation of various drive cycles for estimating an electric four wheeler's energy utilisation for efficacious performance |

Energy Storage |

5 |

4 |

- |

|

|

21 |

L. V. Awadhani, Anand Bewoor |

Behavior of Composite Bolted Joint Under Tension-Shear and Compression-Shear Load Cases |

International Review of Mechanical Engineering |

17 |

1 |

39-47 |

|

|

22 |

Mahadev Madgule, C. G. Shreenivasa, and A. V. Borgaonkar |

Effect of influencing parameters on developing aluminium metal foam by using powder metallurgy technique with a foaming agent as a wax powder |

Journal of Porous Materials, Springer |

30 |

3 |

1021-1036 |

|

|

23 |

Rajeswari K., |

Time Series Analysis with Systematic Survey on Covid-19 Based Predictive Studies During Pandemic Period using Enhanced Machine Learning Techniques |

International journal of online and biomedical engineering |

19 |

7 |

160-183 |

|

|

24 |

U. I. Shaikh, S. Kale, A. Roy, A. Sur |

Performance analysis of an energy-efficient PCM-based room cooling system |

Frontiers in Heat and Mass Transfer |

20 |

28 |

1-10 |

|

|

25 |

Sagar Wankhede, K. |

Experimental investigation on hybrid cooled lithium-ion battery pack with 3S4P cell configuration using OM 48 as phase change material and heat pipe |

Energy Storage |

- |

- |

- |

|

|

26 |

Rahul Gujar, H. Warhatkar, A. Kale |

Study of Image-Based Finite Element Model for Predicting the Biomechanical Properties of Femur Bone: A Review |

Journal of The Institution of Engineers (India): Series C |

104 |

3 |

661-670 |

|

|

Conference Publications |

|||||||

|

Sr. No. |

Authors name |

Paper Title |

Conference Name/ Proceedings Name |

Vol. |

Issue |

Pages |

DOI |

|

1 |

Sanjay Salve, A. Fulambarkar |

Performance investigation of solar air dryer with and without PCM based heat storage material for agricultural products drying |

AIP Conference Proceedings |

2653 |

1 |

40003 |

|

|

2 |

O. Hendre, P. Kale, and S. More |

Thermal-Static Structural Coupled Analysis of Disc Brake Rotor of Bike Using Ansys |

AIP Conference Proceedings |

2653 |

1 |

5.011086 |

|

|

3 |

S. Sagare, P. Kale, and A. Kashid |

Design of a Helical Coil in Front Suspension System as a Replacement for Torsion Bar Suspension for a Three-Wheeler Vehicle Using FEA |

AIP Conference Proceedings |

2653 |

1 |

5.011087 |

|

|

4 |

H. Shinde, P. Kale, and S. More |

Finite Element Analysis of LPG Cylinder |

AIP Conference Proceedings |

2653 |

1 |

5.011149 |

|

|

5 |

A. Pawar and Sanjay Matekar |

Design of Prosthetic arm |

AIP Conference Proceedings |

2653 |

1 |

5.011042 |

|

|

6 |

S. Anawkar, and Amit Panchwadkar |

Comparison between Levenberg Marquart, Bayesian and Scaled Conjugate Algorithm for Prediction of Cutting Forces in Face Milling Operation |

AIP Conference Proceedings |

2653 |

1 |

5.011109 |

|

|

7 |

S. Anawkar, and Amit Panchwadkar |

Crack Detection Using Image Processing |

AIP Conference Proceedings |

2653 |

1 |

5.011689 |

|

|

8 |

C. L. Ladekar, A. Pise, M. Nukulwar, and A. Lingayat |

Comparative analysis of integrated heat sink vapor chamber with conventional heat sink |

Materials Today: Proceedings |

72 |

3 |

1136-1142 |

|

|

9 |

S. Jamadar, R. Yawale, M. Kolhe, A. Hood, and Nilesh Gaikwad |

Design and manufacturing of cooling system for FSAE car |

Materials Today: Proceedings |

77 |

3 |

905-915 |

|

|

10 |

S. Mirajgave, S. Mhase, M. Potu, and Nilesh Gaikwad |

Design and cost effective manufacturing of swivelling brake master cylinder for a formula student vehicle |

Materials Today: Proceedings |

77 |

3 |

977-982 |

|

|

11 |

Mahadev Madgule, N Vinayaka, Y. M. Sonkhaskar, D. R. Patel, R. Karthikeyan, and P. Selvakumar |

Mechanical properties and microstructure of activated TIG welded similar joints of Inconel alloys by desirability approaches |

Materials Today: Proceedings |

77 |

2 |

528-533 |

|

|

12 |

Jeet P. Patil, Raju B. Bhosale, U. Mane |

Effect of lubrication on contact thermoforming: Thermal aspect |

Materials Today: Proceedings |

72 |

3 |

672-678 |

|

|

13 |

V. Sagare, P. R. Kale, A. Roy, and R. B. Patil |

Experimental investigation of parameters influencing battery life cycle of lithium-ion batteries at ambient cell surface temperature |

Materials Today: Proceedings |

77 |

3 |

631-639 |

|

|

14 |

O. Hendre, P. Kale, R. gore, and N. Pardeshi |

Numerical study of water-cooling jacket of a diesel engine using coupled field analysis |

Materials Today: Proceedings |

77 |

3 |

739-747 |

|

|

15 |

S. Taware, Sanjay Matekar, P. Deore |

Study of flow characteristics of air through soot blower nozzles using numerical method |

Materials Today: Proceedings |

77 |

3 |

||

|

16 |

A. R. Salve, C. L. Ladekar, A. Lingayat, and S. J. Sonawane |

Numerical modeling of reactor cooling system to extract the unsteady heat generated during the electrochemical synthesis of nanoparticles |

Materials Today: Proceedings |

77 |

3 |

754-763 |

|

|

17 |

C. Kothare, C. Ladekar, and S. Kongre |

Experimental investigation of N-Butanol as a fuel additive for Spark Ignition (S.I.) Engine |

Materials Today: Proceedings |

77 |

3 |

946-952 |

|

|

18 |

U. Potdar, P. Waghmare, P. Joshi, N. Patil, and S. Varpe |

Thermal design of standalone miniature thermo-electric power conversion system using variable area liquid fuel combustor |

Materials Today: Proceedings |

77 |

3 |

698-703 |

|

|

19 |

D. V. Honrao, and Laxman Awadhani |

Design and development of agricultural spraying system |

Materials Today: Proceedings |

77 |

3 |

734-738 |

|

|

20 |

Jayashri Wagh, M. Madgule, and L. V. Awadhani |

Investigative studies on the mechanical behavior of Jute, Sisal, Hemp, and glass fiber-based composite material |

Materials Today: Proceedings |

77 |

3 |

969-976 |

|

|

21 |

P. Bhonde, and Amit Panchwadkar |

Automatic detection of bearing faults |

Materials Today: Proceedings |

77 |

3 |

586-591 |

|

|

22 |

D. Pansare, Amit Panchwadkar, and O. Joshi |

Enveloping behaviour of tire using iterative points method |

Materials Today: Proceedings |

77 |

3 |

813-817 |

|

|

23 |

Rita Pimpalkar, A. Sahu, R. B. Patil, A. Roy |

A Comprehensive Review on Failure Modes and Effects Analysis of Solar Photovoltaic System |

Materials Today: Proceedings |

77 |

3 |

687-691 |

|

|

24 |

V. Chiplunkar, R. Gujar, A. Adiverekar, R. Kulkarni, A. Thonge |

Computational fluid dynamics analysis for an active rear-wing design to improve cornering speed for a high-performance car |

Materials Today: Proceedings |

77 |

3 |

887-896 |

|

|

25 |

H. Bhamre, S. Deshmukh, H. Shintre, P. Ghodke, S. Shinde |

Design and development of bottle sorting machine using Arduino |

Materials Today: Proceedings |

77 |

3 |

1023-1027 |

|

|

26 |

V. G. Talkit, P. Honrao, S. Bhosale, A. Bewoor, Rajkumar B. Patil |

Application of the Reliability Analysis for Modifications in Maintenance Scheduling |

Materials Today: Proceedings |

77 |

3 |

579-583 |

|

|

27 |

V. Talkit, R. Kininge, P. Kokate, D. Narkhede, S. Madane, A. Bewoor, Rajkumar B. Patil |

Reliability Analysis of Repairable and Replaceable System: A Case Study of a Dairy Product Industry |

Materials Today: Proceedings |

77 |

3 |

573-580 |

|

|

28 |

S. S. Shinde, P. V. Deshmukh, and Rajkumar B. Patil |

Analyzing the Side Effects of Increasing E-Pollution on the Life and Nature |

Materials Today: Proceedings |

77 |

3 |

592-596 |

|

|

29 |

M. A. Mellal, S. Al-Dahidi, Rajkumar B., Patil, B. S. Kothavale, R. S. Powar |

System Reliability-Redundancy Optimization with High-Level of Subsystems |

Materials Today: Proceedings |

77 |

3 |

627-630 |

|

|

30 |

Jeet P. Patil, Raju B. Bhosale, U. Mane |

Effect of lubrication on contact thermoforming: Thermal aspect |

Materials Today: Proceedings |

72 |

3 |

672-678 |

|

|

31 |

G. R. Chavhan, G. R. Chavhan, L. N. Wankhade, M. R. Nukulwar, P. V. Chilbule, S. C. Jamunkar |

Investigation of wear and mechanical properties of hybrid polymer composites |

Materials Today: Proceedings |

||||

|

32 |

A. R. Warade, G. B. Shinde, R. W. Gaikwad, V. S. Hakke, S. H. Sonawane, Abhay Lingayat |

Intensification of pharmaceutical wastewater treatment using hydrodynamic cavitation process |

Materials Today: Proceedings |

77 |

3 |

692-697 |

|

|

33 |

A. V. Borgaonkar, M. B. Mandale, S. B. Potdar, Mahadev Madgule |

Experimental and finite element investigation of statistical energy analysis parameters for idealized subsystems |

Materials Today: Proceedings |

77 |

3 |

680-686 |

|

|

34 |

Mahadev Madgule, C. G. Shrenivasa, and A. V. Borgaonkar |

Aluminium metal foam production methods, properties and applications- a review |

Materials Today: Proceedings |

77 |

3 |

673-679 |

|

|

35 |

Dhiraj Mali, and Amrita Francis |

Design analysis and performance evaluation of a self-locking hydrostatic differential for automated agriculture spray vehicle |

Materials Today: Proceedings |

77 |

3 |

838-847 |

|

|

36 |

S. B. Solepatil, and N. R. Deore |

Performance analysis of compliant mechanism for micro positioning stage |

Proceedings on Engineering Sciences |

5 |

2 |

303-310 |

10.24874/PES05.02.013 |

|

37 |

V. Y. Bhalerao, S. S. Lakade, and A. V. Borgaonkar |

The effect of boron nitride nanoparticles on 100Cr6 steel's mechanical and tribological properties after vacuum heat treatment |

Materials Today: Proceedings |

77 |

3 |

941-945 |

|